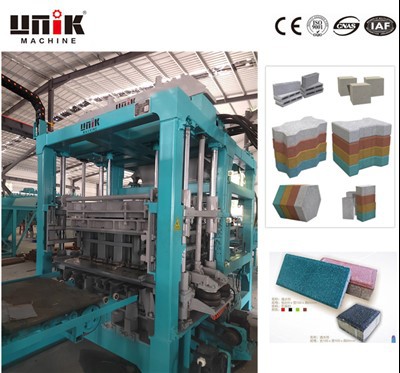

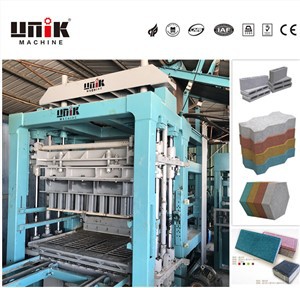

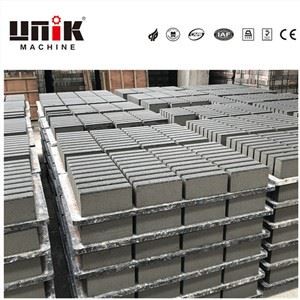

Concrete Hollow Block Machine Equipment is a mechanical equipment for the production of concrete hollow bricks, which is made of high-strength steel and equipped with an electric motor and hydraulic system. It can produce a large number of high-quality and lightweight hollow bricks in a short time, with the characteristics of high efficiency, stability and reliability. In the production process of Concrete Hollow Block Machine Equipment, concrete material is injected into the formwork, and then compacted and shaped by high pressure and vibration to form high-quality hollow bricks. The advantages of Concrete Hollow Block Machine Equipment include high production efficiency, high degree of automation, simple operation, low cost and customization, etc., which is very suitable for construction sites such as construction sites, factories, and shopping malls. Concrete Hollow Block Machine Equipment is suitable for many construction fields, such as residential buildings, public buildings, roads, bridges, tunnels, etc. Concrete Hollow Block Machine Equipment can make hollow bricks with different materials such as clay, plaster, sand, gypsum, etc., making it suitable for the needs of various construction fields. Due to its high efficiency, stability and customizability, Concrete Hollow Block Machine Equipment plays a very important role in the production process of modern construction projects, effectively improving work efficiency and production efficiency, and reducing labor costs and production costs.